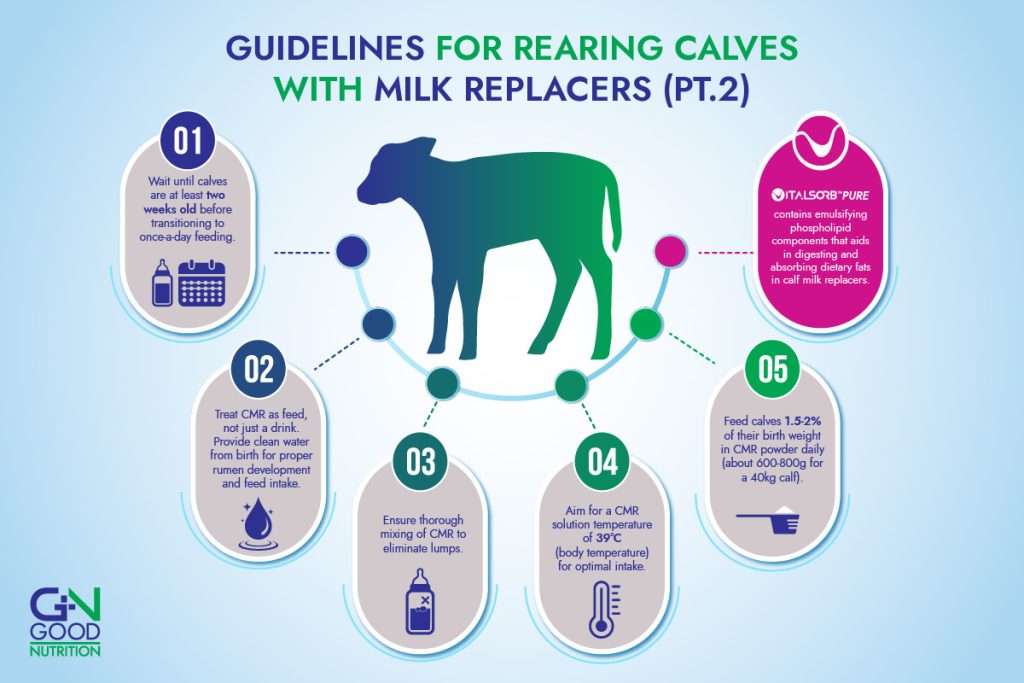

Guidelines For Rearing Calves With Milk Replacers Part 2

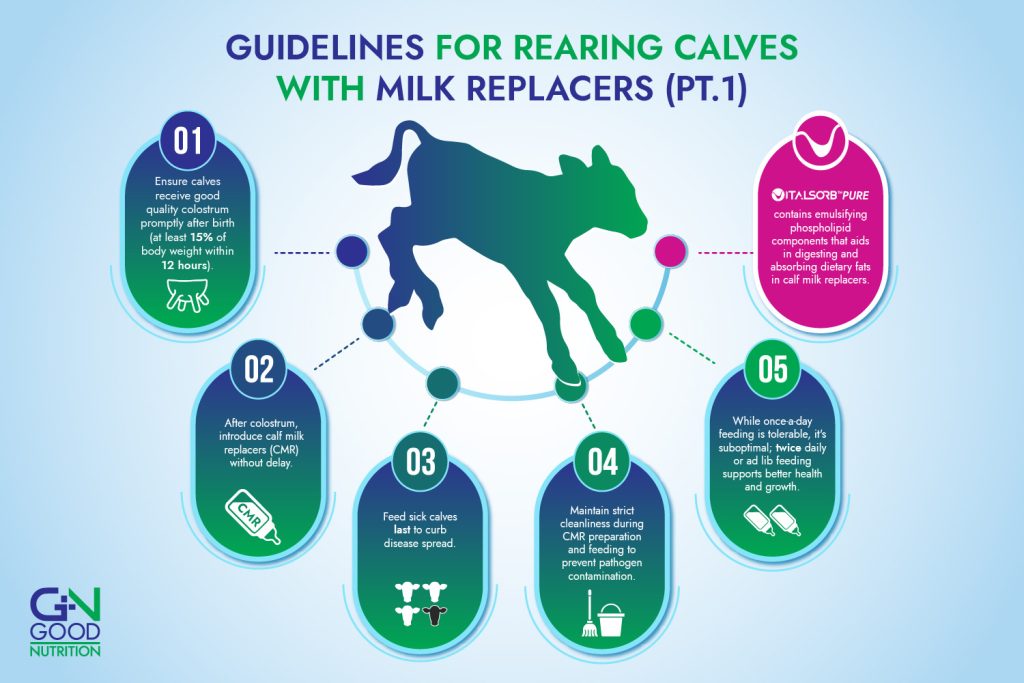

The feeding and management of calves greatly influence their lifelong performance. Thus, it’s vital to regard these practices as investments, not expenses. We’re presenting a series of guidelines followed by farmers, emphasizing the crucial role of Vitalsorb Pure lysolecithin in this regard.

1. If wanting to move to once a day feeding, it is ideal to wait until the calves are at least two weeks of age.

2. Consider CMR as a feed, not a drink. Ad-lib clean water is essential from birth for good rumen development and feed intake.

3. Mix CMR thoroughly, ensure there are no lumps.

4. The optimal drinking temperature of CMR solution is 39°C (body temperature).

5. Feeding calves 1.5-2% of their birth weight in CMR powder daily (about 600-800g of CMR solids daily for a 40kg calf). The amount of calf milk replacer fed at each meal depends on the number of times a day you feed, target growth rate, and the fat and protein content of the CMR.

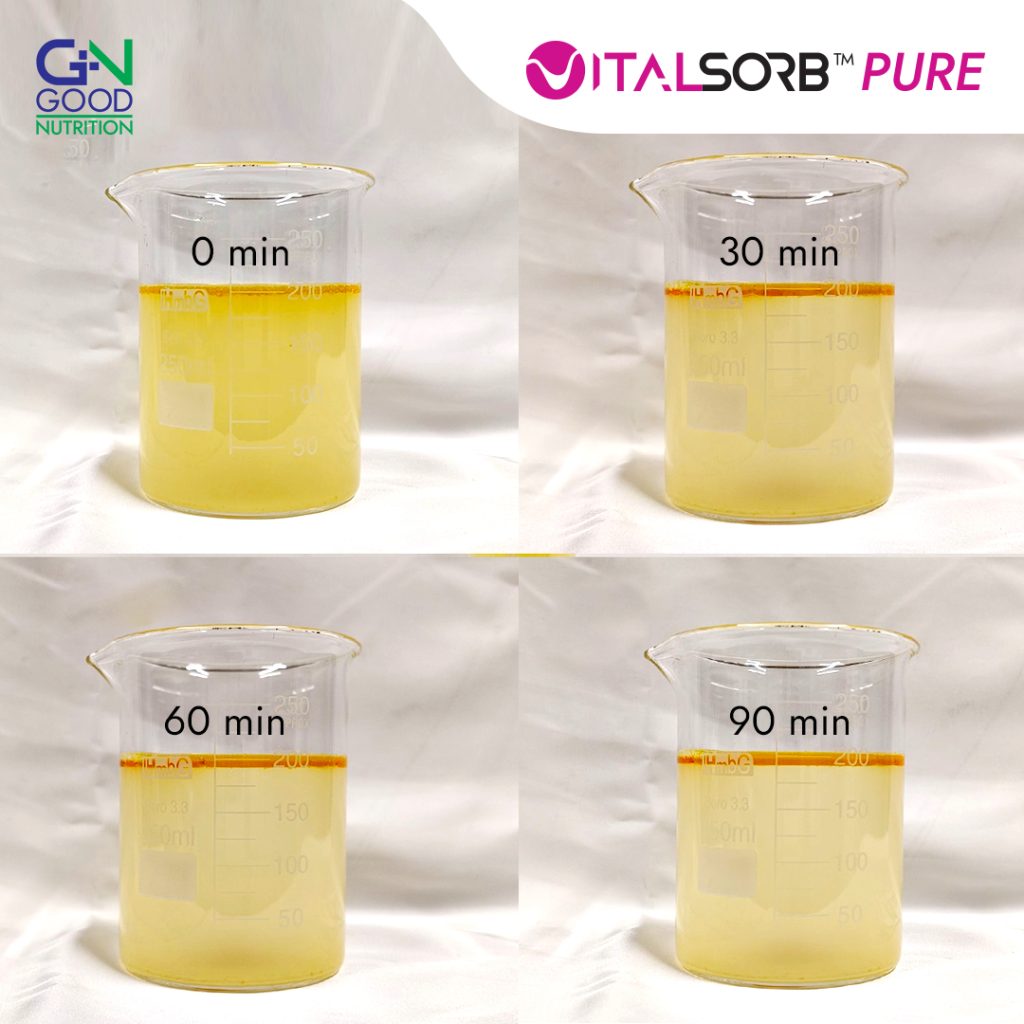

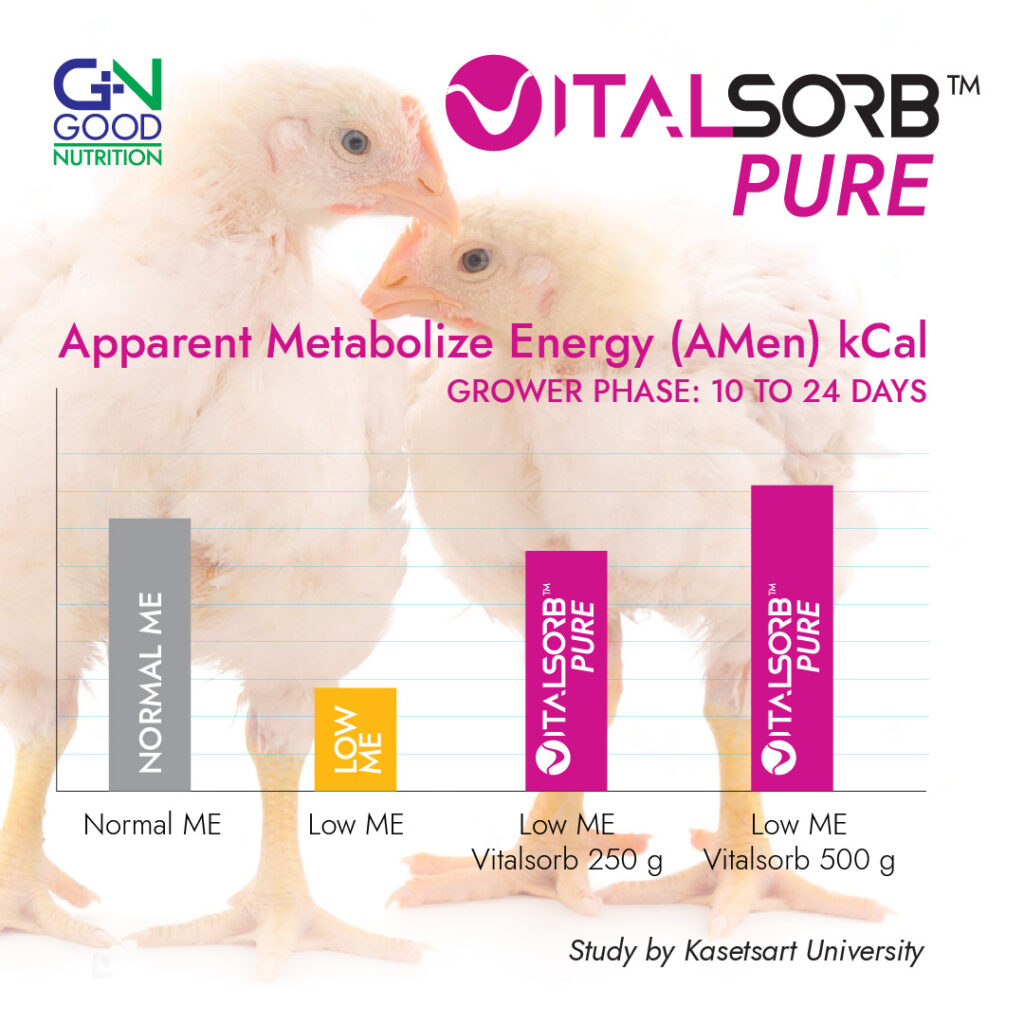

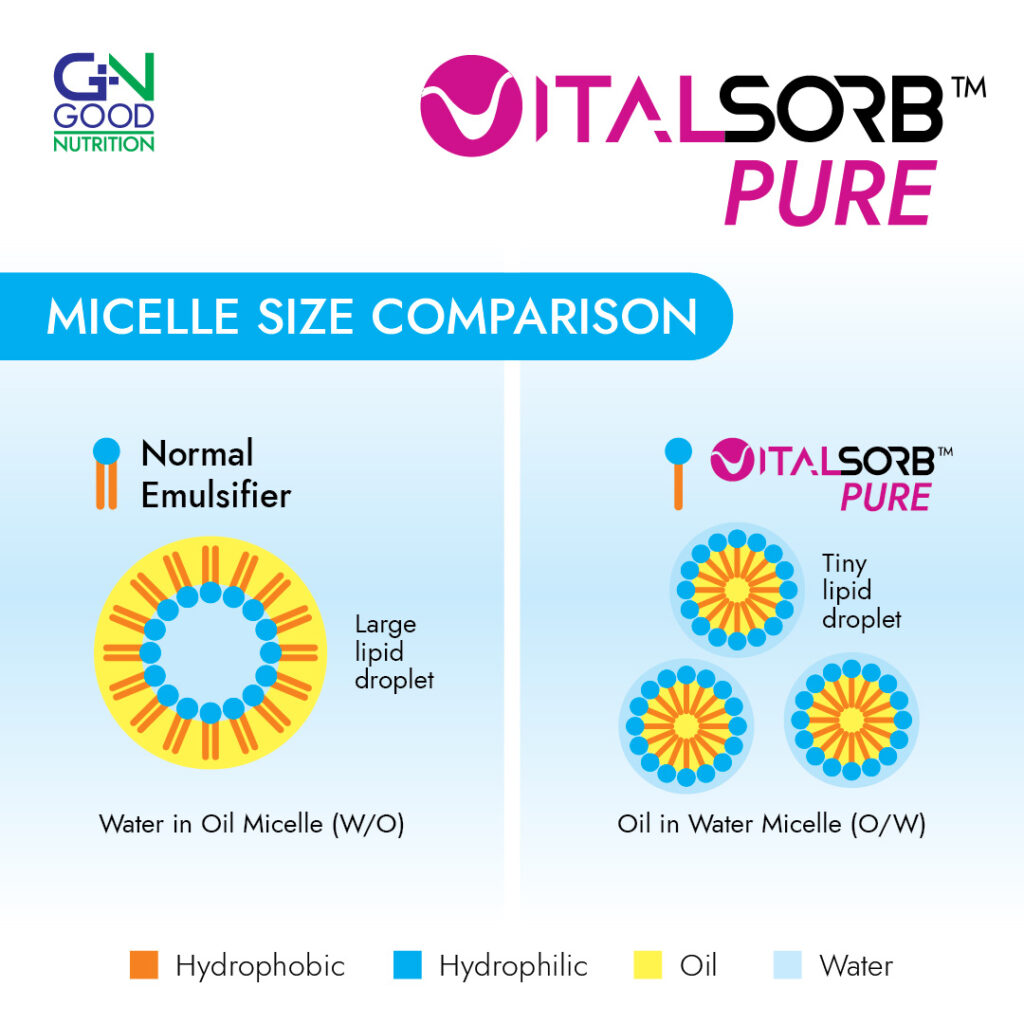

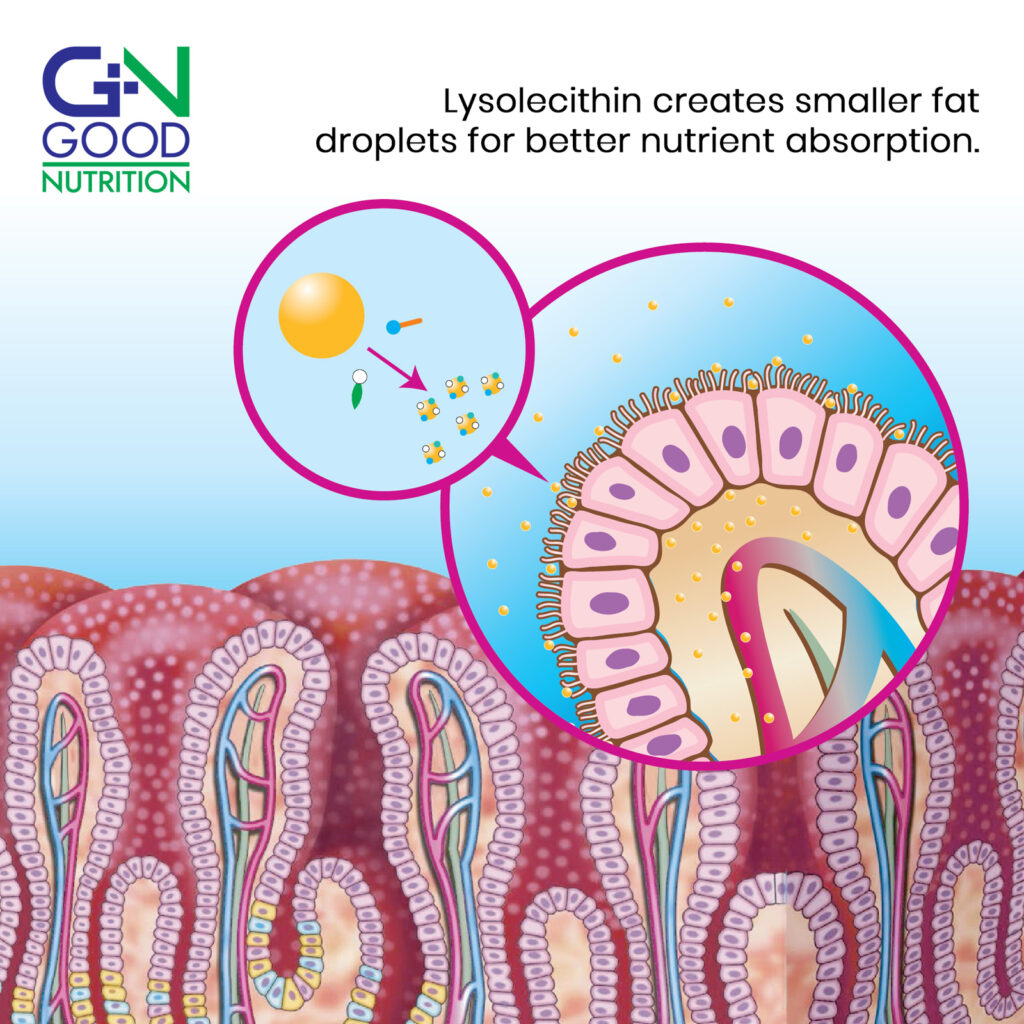

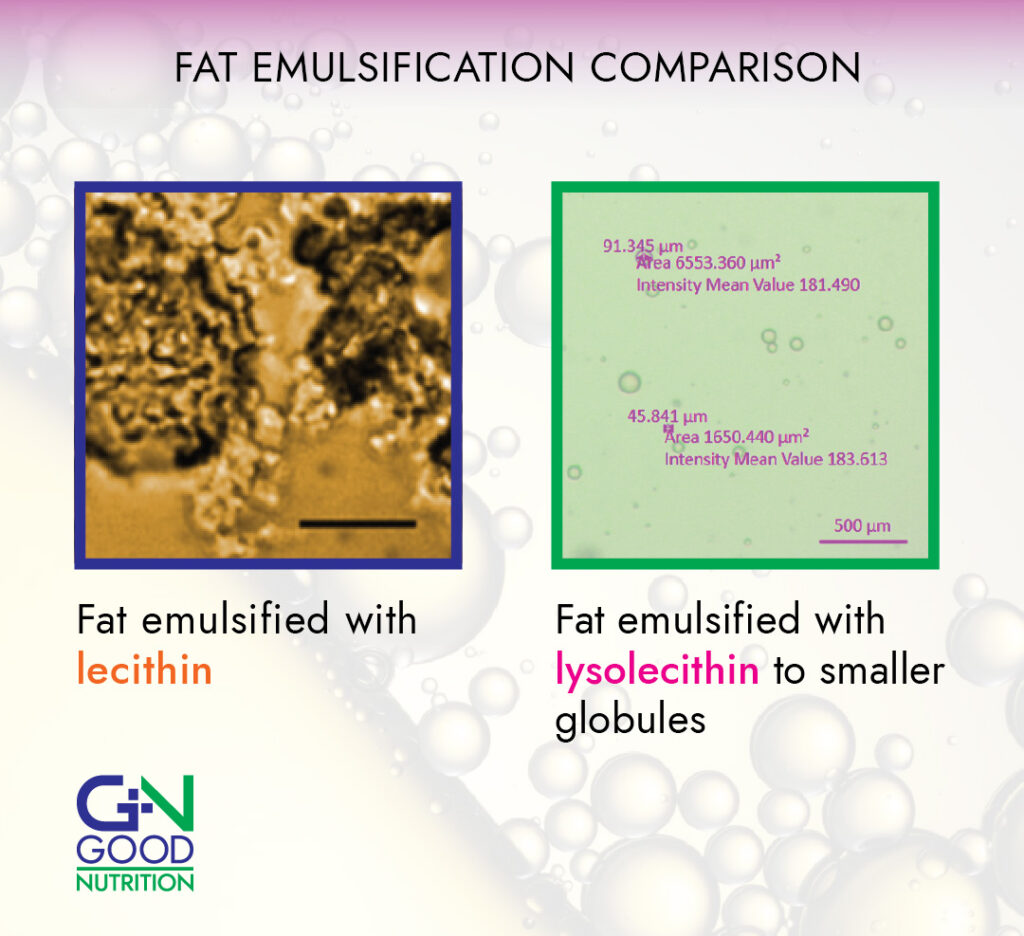

Vitalsorb™ Pure is an emulsifying agent containing phospholipid components to support oil-in-water emulsions for the superior digestion and absorption of dietary fats and oils, particularly saturated fats.