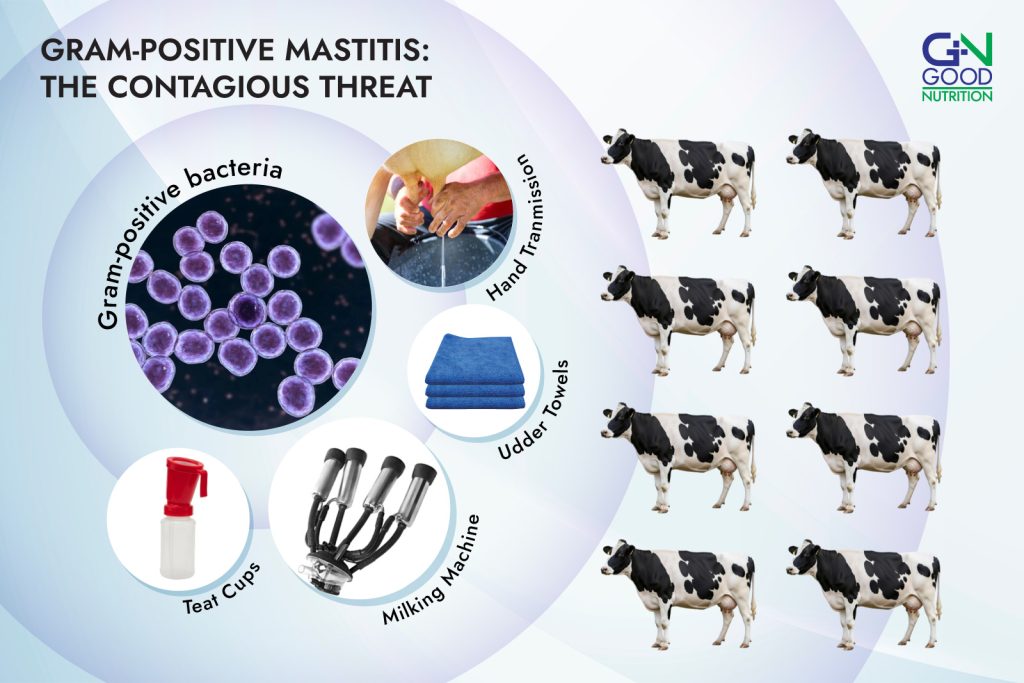

Research confirms that gram-positive bacterial infections in mastitis severely affect milk production, are highly contagious between cows, and lead to chronic infections. Evidence also supports monolaurin as an effective antimicrobial agent against these pathogens.

Severe Impact on Milk Production

Gram-positive mastitis pathogens cause significant production losses through multiple mechanisms:

Direct Production Decreases: Studies show that Staphylococcus aureus mastitis results in substantial milk production losses, with infected cows showing chronically reduced milk yield compared to uninfected animals. Even subclinical infections cause persistent decreases in milk production that can last for months or entire lactations.

Economic Impact: Research indicates that gram-positive cases cause approximately 128-133 kg milk loss over 50 days following clinical mastitis, representing substantial economic losses to dairy operations. The chronic nature of these infections means production losses persist much longer than with environmental pathogens.

Tissue Damage: Gram-positive bacteria produce degradative enzymes and toxins that irreversibly damage milking tissue, ultimately decreasing milk production capacity permanently. *Staphylococcus aureus* particularly causes abscess formation within milk-producing tissues, significantly reducing milk production.

Highly Contagious Nature

Multiple scientific studies demonstrate the contagious characteristics of gram-positive mastitis pathogens:

Cow-to-Cow Transmission: *Staphylococcus aureus* is highly contagious and spreads primarily during the milking process through contaminated milking equipment, milkers’ hands, and contact between infected and uninfected cows. Research shows this pathogen spreads from cow to cow primarily during milking.

Rapid Herd Spread: Studies classify *Staphylococcus aureus* and *Streptococcus agalactiae* as contagious pathogens that show rapid spread in a herd resulting in large numbers of infected animals. Cornell University research confirms that infected cows are always the source of new infections for *Streptococcus agalactiae*.

Reservoir and Transmission: The primary reservoirs are infected udders, teat canals, and teat lesions, with bacteria spreading through mechanical transfer via milking equipment, hands, and contaminated materials. Research demonstrates that contaminated milking equipment can spread bacteria from one udder to the next.

Herd-Level Impact: Studies show that in dairy farms with high bulk tank milk somatic cell counts, cow-level prevalence of *S. aureus* infections may increase to 50-75%with individual quarter prevalence of 10-25%. This contrasts sharply with environmental pathogens that rarely exceed 5% quarter prevalence.

Chronic Mastitis Development

Scientific evidence consistently shows gram-positive bacteria cause chronic, persistent infections:

Biofilm Formation: Research demonstrates that both *Staphylococcus aureus* and *Streptococcus agalactiae* form protective biofilms within the udder, making them resistant to immune responses and antibiotics. Studies show all *S. agalactiae* isolates produced biofilm, with 58.6% classified as strong producers.

Persistent Infections: *Staphylococcus aureus* commonly produces chronic infections that persist from one lactation to another despite dry cow therapy. Research indicates these bacteria can survive indefinitely in mammary glands by forming biofilms.

Treatment Resistance: Scientific studies show that antibiotic treatment of *S. aureus* infections are not effective, with very low cure rates. The ability to form biofilms and adapt to host environments makes them harder targets for treatment.

Monolaurin Efficacy Against Gram-Positive Mastitis Pathogens

Extensive research supports monolaurin’s antimicrobial activity against gram-positive mastitis pathogens:

Broad-Spectrum Activity: Multiple studies demonstrate that monolaurin exhibits significant antimicrobial activity against *Staphylococcus aureus* with MIC values ranging from 250-2000 μg/mL. Research shows 100% sensitivity rates of gram-positive bacteria including *Staphylococcus aureus* and *Streptococcus* species to monolaurin.

Clinical Trial Results: A controlled study in buffalo with subclinical mastitis showed 90% recovery rate when monolaurin was combined with antioxidants, compared to 70% with antioxidants alone[20]. The study concluded that monolaurin addition significantly improved therapeutic efficacy[20].

Mechanism of Action: Research shows monolaurin disrupts bacterial cell walls and membranes, with scanning electron microscopy revealing cell elongation and swelling in *S. aureus* outer membrane after treatment. Studies demonstrate monolaurin reduces β-lactamase gene expression by 71-88%, potentially overcoming antibiotic resistance.

Synergistic Effects: Clinical studies show synergistic effects between monolaurin and β-lactam antibiotics with synergism rates of 83.3-100% against *Staphylococcus aureus*. This combination allows for reduced antibiotic dosages while maintaining effectiveness.

Biofilm Disruption: Research demonstrates monolaurin’s ability to inhibit biofilm formation and eradicate pre-existing biofilms formed by MRSA, with dose-dependent inhibitory effects. Studies show monolaurin reduces bacterial cell attachment and biofilm formation compared to controls.

Sources

[1] Staph aureus Herd Infection Control https://www.vet.cornell.edu/animal-health-diagnostic-center/testing/testing-protocols-interpretations/staph-aureus-herd-infection-control

[2] [PDF] Staphylococcus aureus Mastitis: Cause, Detection, and Control https://vtechworks.lib.vt.edu/bitstreams/dde1c303-aead-4161-b3ee-d14777a4b82d/download

[3] Staphylococcus Aureus Mastitis: Cause, Detection, and Control https://www.thecattlesite.com/articles/679/staphylococcus-aureus-mastitis-cause-detection-and-control

[4] Effects of repeated gram-positive and gram-negative clinical mastitis … https://pubmed.ncbi.nlm.nih.gov/19528587/

[5] Bovine mastitis: risk factors, therapeutic strategies, and alternative … https://pmc.ncbi.nlm.nih.gov/articles/PMC7649072/

[6] Staphylococcus aureus from Subclinical Cases of Mastitis in Dairy … https://pmc.ncbi.nlm.nih.gov/articles/PMC9781172/

[7] Signs of Staphylococcus aureus infections in dairy cows | Farmlab https://farmlab.ie/what-are-the-signs-of-staphylococcus-aureus-infections-in-dairy-cows/

[8] A practical look at contagious mastitis – Dairy Producer https://www.dairyproducer.com/a-practical-look-at-contagious-mastitis-2/

[9] Contagious Mastitis – DairyNZ https://www.dairynz.co.nz/animal/mastitis/contagious-mastitis/

[10] The epidemiology of Staphylococcus aureus infections from … https://www.sciencedirect.com/science/article/abs/pii/S0378113503002049

[11] Streptococcus agalactiae (Strep ag) https://www.vet.cornell.edu/animal-health-diagnostic-center/testing/testing-protocols-interpretations/streptococcus-agalactiae-strep-ag

[12] Staphylococcal mastitis in dairy cows – PMC – PubMed Central https://pmc.ncbi.nlm.nih.gov/articles/PMC11165426/

[13] Coliform mastitis – Veterinary Research, a journal on Animal Infection https://www.vetres.org/articles/vetres/pdf/2003/05/V3503.pdf

[14] Biofilm formation by Streptococcus agalactiae – PubMed Central https://pmc.ncbi.nlm.nih.gov/articles/PMC4316791/

[15] Relationship between Biofilm Production and High Somatic Cell … https://pmc.ncbi.nlm.nih.gov/articles/PMC9966988/

[16] The Role of Streptococcus spp. in Bovine Mastitis – PubMed Central https://pmc.ncbi.nlm.nih.gov/articles/PMC8305581/

[17] Novel synergistic interactions between monolaurin, a mono-acyl … https://bmcinfectdis.biomedcentral.com/articles/10.1186/s12879-024-09261-9

[18] Antimicrobial and Antibiofilm Activity of Monolaurin against … https://pmc.ncbi.nlm.nih.gov/articles/PMC11315973/

[19] Novel Antibacterial Activity of Monolaurin Compared with … https://jddonline.com/articles/novel-antibacterial-activity-of-monolaurin-compared-with-conventional-antibiotics-against-organisms-S1545961607P0991X

[20] [PDF] efficacy of monolaurin in treatment of subclinical mastitis as … – KUOJS https://kuojs.lib.ku.ac.th/index.php/BufBu/article/download/4062/2791/25253

[21] Novel synergistic interactions between monolaurin, a mono-acyl … https://pmc.ncbi.nlm.nih.gov/articles/PMC11000382/

[22] Streptococcus bacteria cause mastitis – Farmlab Diagnostics https://farmlab.ie/how-does-streptococcus-cause-mastitis-in-cattle/

[23] Bovine Diagnostics – Mastitis Diagnosis | The Cattle Site https://www.thecattlesite.com/focus/thermo-fisher-scientific/2336/bovine-diagnostics-mastitis-diagnosis

[24] Multidrug Resistance and Molecular Characterization of … – Frontiers https://www.frontiersin.org/journals/cellular-and-infection-microbiology/articles/10.3389/fcimb.2021.647324/full

[25] Staphylococcal mastitis in dairy cows – Frontiers https://www.frontiersin.org/journals/veterinary-science/articles/10.3389/fvets.2024.1356259/full

[26] Streptococcus agalactiae Mastitis in Dairy Herds https://www.addl.purdue.edu/newsletters/2002/spring/samdh.shtml

[27] Understanding Mastitis: Causes, Types, & Solutions – Bovonic https://bovonic.com/understanding-mastitis/

[28] Contagious Mastitis – AHS – Current News – Department of Agriculture https://www.animalhealthsurveillance.agriculture.gov.ie/currentnews/contagiousmastitis.html

[29] Mastitis in Cattle – Reproductive System – MSD Veterinary Manual https://www.msdvetmanual.com/reproductive-system/mastitis-in-large-animals/mastitis-in-cattle

[30] Mastitis-Causing Pathogens and How They Get on Your Farm https://extension.psu.edu/mastitis-causing-pathogens-and-how-they-get-on-your-farm/

[31] Prevalence of contagious mastitis pathogens in bulk tank milk in … https://pmc.ncbi.nlm.nih.gov/articles/PMC1461414/

[32] Relationship: Mastitis and monolaurin – Caring Sunshine https://caringsunshine.com/relationships/relationship-mastitis-and-monolaurin-2/

[33] Antibacterial study of the medium chain fatty acids and their 1 … https://pubmed.ncbi.nlm.nih.gov/19469285/

[34] Measuring the Antimicrobial Activity of Lauric Acid against Various … https://pmc.ncbi.nlm.nih.gov/articles/PMC6923562/

[35] [PDF] Antimicrobial Effect of a Lauric Acid on Streptococcus Mutans Biofilm. http://www.aimdrjournal.com/wp-content/uploads/2021/11/21.-OA_Woo_2_4_37.pdf

[36] Monolaurin inhibits antibiotic-resistant Staphylococcus aureus in … https://www.nature.com/articles/s41598-025-05667-w

[37] Efficacy of monolaurin in treatment of subclinical mastitis as … – KUOJS https://kuojs.lib.ku.ac.th/index.php/BufBu/article/view/4062

[38] Insect Derived Lauric Acid as Promising Alternative Strategy to … https://www.frontiersin.org/journals/microbiology/articles/10.3389/fmicb.2021.620798/full

[39] Synergistic interactions between antimicrobial peptides derived from … https://pmc.ncbi.nlm.nih.gov/articles/PMC5557623/

[40] Antibacterial Effect of Caprylic Acid and Monocaprylin on Major … https://www.sciencedirect.com/science/article/pii/S0022030205730332

[41] Antibacterial fatty acids: An update of possible mechanisms of action … https://www.sciencedirect.com/science/article/pii/S0163782721000096

[42] Antimicrobial and Antibiofilm Activity of Monolaurin against … https://onlinelibrary.wiley.com/doi/10.1155/2024/7518368

[43] [PDF] Control of Bovine Mastitis: Old and Recent Therapeutic Approaches https://core.ac.uk/download/pdf/55641346.pdf

[44] Antibacterial Activity of Sphingoid Bases and Fatty Acids against … https://journals.asm.org/doi/10.1128/aac.05151-11

[45] The 1-monolaurin inhibit growth and eradicate the biofilm formed by … https://bmcproc.biomedcentral.com/articles/10.1186/s12919-019-0174-9

[46] In Vitro Antibacterial Activities and Mechanisms of Action of Fatty … https://www.sciencedirect.com/science/article/pii/S0362028X22101444

[47] The role of staphylococci in subclinical mastitis of cows and lytic … https://pmc.ncbi.nlm.nih.gov/articles/PMC5771174/

[48] Advances in understanding Gram-positive mastitis on farms – Dairy https://www.canr.msu.edu/news/advances-in-understanding-gram-positive-mastitis-on-farms

[49] Virulence and resistance profiling of Staphylococcus aureus isolated … https://www.nature.com/articles/s41598-024-65448-9

[50] Detection of Biofilm Forming Streptococcus species from Bovine … https://journals.acspublisher.com/index.php/ijvsbt/article/view/3438

[51] [PDF] Antimicrobial Resistance of Biofilm-Forming Streptococcus … https://www.hilarispublisher.com/open-access/antimicrobial-resistance-of-biofilmforming-streptococcus-agalactiaeisolated-from-bovine-mastitis-2157-7579-1000374.pdf

[52] Back to the basics: Gram-negative vs. gram-positive mastitis https://www.agproud.com/articles/59218-back-to-the-basics-gram-negative-vs-gram-positive-mastitis

[53] [PDF] Biofilm formation on different pH conditions by Streptococcus … https://enviromicro-journals.onlinelibrary.wiley.com/doi/am-pdf/10.1111/lam.13015

[54] Diversity and pathogenesis of Staphylococcus aureus from bovine … https://bmcvetres.biomedcentral.com/articles/10.1186/s12917-022-03197-5

[55] Biofilm production and other virulence factors in Streptococcus spp … https://bmcvetres.biomedcentral.com/articles/10.1186/s12917-017-1322-y

[56] The effect of recurrent episodes of clinical mastitis caused by gram … https://www.sciencedirect.com/science/article/pii/S002203021100508X

[57] Molecular characteristics of Staphylococcus aureus strains isolated … https://www.frontiersin.org/journals/veterinary-science/articles/10.3389/fvets.2023.1177302/full